- Features

- Qualification

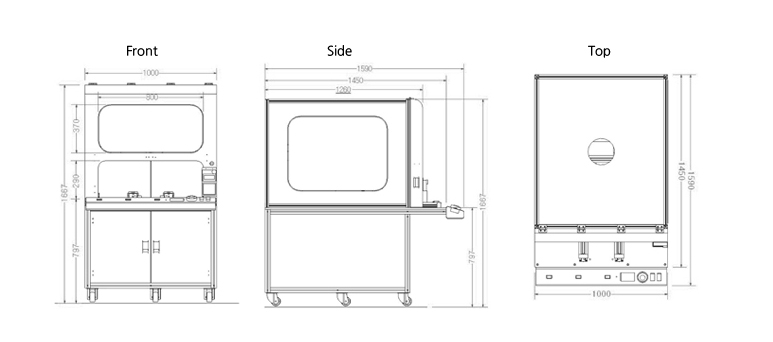

- Outer size

TWIN SHUTTLE

Home > Products > Soldering-only > Twin shuttle

|

- Equipped with 3rd generation soldering robot L-CAT NEO with 999 soldering conditions with different temperature settings for each program and work point |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||