Lead-free Wire Soldier recommended by our company

It is non-annual lead verified for robot soldering by our company, and it is non-annual lead used by many domestic and foreign companies.

Even the same maker has several specifications, so please check the specifications below. (The same applies to manual soldering)

| Ishigawa (J3-MRK Series) |

Kester (245 series) |

Senju (ECO-RMA)(Sparkle-ESC21) |

|

|

|

- Response to lead ball scattering

- Rosin Flux

- Flux Response in the 2% to 6% range

- 0.2 Ø Wire solder

- High-temperature, high-speed

soldering glass |

- Response to lead ball scattering

- Resin Flux (low residue Flux)

- Flux content 2.4%, 3.3%, 6%

- 0.4 Ø Wire solder

- Flux gas pinhole defective response

glass |

- Lead ball acid response

- Rosin Flux

- Flux 3% and 4%

- 0.4 Ø Wire solder

|

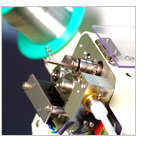

This test was prepared for the purpose of comparing the soldering properties of general lead and lead-free lead and N2 gas recruitment when using lead-free lead, and the test was limited to one time for 7 types of lead-free domestic and foreign products on the market.

Test under the same conditions regardless of the melting point and ingredients of pb free, mark A, B, and C regardless of the company.

| [Review Opinion]

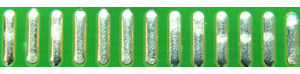

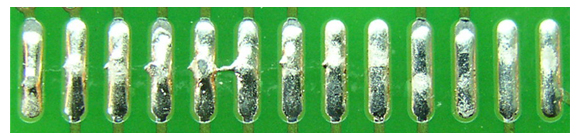

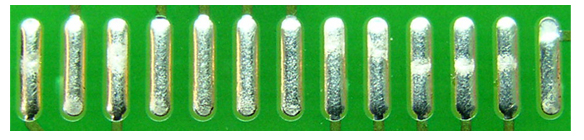

The pb free using the high-temperature Rosin Flux system was generally good, and in the case of the pb free using Resin Flux, there seemed to be a problem in the generation of surface tension. In the case of the pb free soldering without N2 gas, the initial symptoms and bridge phenomena of horn soldering and horn soldering were shown as shown in the picture below.

There seemed to be differences in quality by company, flux content, and ingredients, and reliability tests such as separate tensile force tests were not conducted.

|

pb free soldering (Sn Ag3.0 Cu0.5 Flux2.5%) pb free soldering (Sn Ag3.0 Cu0.5 Flux2.5%)

pb free soldering N2 gas use (Sn Ag3.0 Cu0.5 Flux2.5%) pb free soldering N2 gas use (Sn Ag3.0 Cu0.5 Flux2.5%)

Testing Conditions and Environment Testing Conditions and Environment

|

|

|

|

|

|

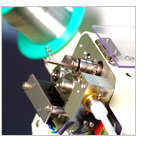

facilities used

L-CAT NEO |

Test temperature

360 ±3 °C |

Built-in Robots

Using N2 |

Used PCB

FR-4 Section |

pb free

Ø0.67 species |

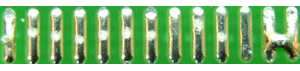

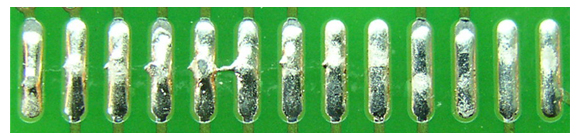

Comparative Test of General Soldering and Lead-free Soldering Comparative Test of General Soldering and Lead-free Soldering

| General lead N2 gas not used |

pb free solder N2 gas not used |

pb free solder N2 gas used |

|

|

|

1. Wire solder :sn,pb, Ø 0.6

Flux 3.0%

2. Test temperature: 360°

3. Test facility: L-CAT NEO 4430

4.Used PCB: FR-4 Single-Sided

Pattern PCB

|

1. Wire solder :sn96.5 ,Ag3.0 ,Cu0.5,

Ø0.6 Flux 6.0%

2. Test temperature: 360°

3. Test facility: L-CAT NEO 4430

4.Used PCB: FR-4 Single-Sided

Pattern PCB

*Initial phenomenon of horn soldering in the middle part |

1. Wire solder :sn96.5 ,Ag3.0 ,Cu0.5, Ø0.6 Flux 6.0%

2. Test temperature: 360°

3. Test facility: L-CAT NEO 4430

4.Used PCB: FR-4 Single-Sided

Pattern PCB

5. N2 gas pressure:0.5

|

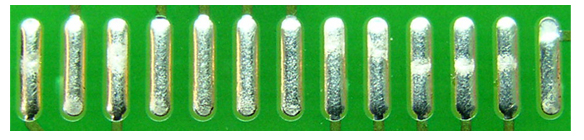

Test by type of lead-free and N2 gas use - B Soldier Test by type of lead-free and N2 gas use - B Soldier

| pb free solder N2 gas not used |

pb free solder N2 gas used |

|

|

1. Wire solder :sn96.5 ,Ag3.0 ,Cu0.5, Ø 0.6. Flux 3.0%

2. Test temperature: 360°

3. Test facility: L-CAT NEO 4430

4. Used PCB: FR-4 Single-Sided Pattern PCB

*There is a phenomenon of horn soldering in the middle part |

1. Wire solder :sn96.5 ,Ag3.0 ,Cu0.5, Ø 0.6. Flux 3.0%

2. Test temperature: 360°

3. Test facility: L-CAT NEO 4430

4. Used PCB: FR-4 Single-Sided Pattern PCB

5.N2 gas pressure:0.5 |

Test by type of lead-free and N2 gas use - C Soldier Test by type of lead-free and N2 gas use - C Soldier

| pb free solder N2 gas not used |

pb free solder N2 gas used |

|

|

1.Wire solder :sn96.5 ,Ag3.0 ,Cu0.5, Ø 0.6. Flux 2.5

2. Test temperature: 360°

3. Test facility: L-CAT NEO 4430

4. Used PCB: FR-4 Single-Sided Pattern PCB

*Initial phenomenon of horn soldering is seen in bridge and middle part |

1.Wire solder :sn96.5 ,Ag3.0 ,Cu0.5, Ø 0.6. Flux 2.5%

2. Test temperature: 360°

3. Test facility: L-CAT NEO 4430

4. Used PCB: FR-4 Single-Sided Pattern PCB

5. N2 gas pressure:0.5 |

Test by type of lead-free and N2 gas use - D Soldier Test by type of lead-free and N2 gas use - D Soldier

KL

| pb free solder N2 gas not used |

pb free solder N2 gas used |

|

|

1.Wire solder :sn96.5 ,Ag3.0 ,Cu0.5, Ø 0.6. Flux 3.0%

2. Test temperature: 360°

3. Test facility: L-CAT NEO 4430

4. Used PCB: FR-4 Single-Sided Pattern PCB

*An initial phenomenon of horn soldering is seen in the middle part |

1.Wire solder :sn96.5 ,Ag3.0 ,Cu0.5, Ø 0.6. Flux 3.0%

2. Test temperature: 360°

3. Test facility: L-CAT NEO 4430

4. Used PCB: FR-4 Single-Sided Pattern PCB

5. N2 gas pressure:0.5

|

Test by type of lead-free and N2 gas use - F Soldier Test by type of lead-free and N2 gas use - F Soldier

| pb free solder N2 gas not used |

pb free solder N2 gas 사used |

|

|

1.Wire solder :sn96.5 ,Ag3.0 ,Cu0.5, Ø 0.6. Flux 2.5%

2. Test temperature: 360°

3. Test facility: L-CAT NEO 4430

4, Used PCB: FR-4 Single-Sided Pattern PCB

*Horn soldering occurs in bridges and middle parts |

1.Wire solder :sn96.5 ,Ag3.0 ,Cu0.5, Ø 0.6. Flux 2.5%

2. Test temperature: 360°

3. Test facility: L-CAT NEO 4430

4, Used PCB: FR-4 Single-Sided Pattern PCB

5. N2 gas pressure:0.5 |

|

pb free soldering (Sn Ag3.0 Cu0.5 Flux2.5%)

pb free soldering (Sn Ag3.0 Cu0.5 Flux2.5%)

pb free soldering N2 gas use (Sn Ag3.0 Cu0.5 Flux2.5%)

pb free soldering N2 gas use (Sn Ag3.0 Cu0.5 Flux2.5%)

Comparative Test of General Soldering and Lead-free Soldering

Comparative Test of General Soldering and Lead-free Soldering

Test by type of lead-free and N2 gas use - B Soldier

Test by type of lead-free and N2 gas use - B Soldier

Test by type of lead-free and N2 gas use - C Soldier

Test by type of lead-free and N2 gas use - C Soldier

Test by type of lead-free and N2 gas use - D Soldier

Test by type of lead-free and N2 gas use - D Soldier

Test by type of lead-free and N2 gas use - F Soldier

Test by type of lead-free and N2 gas use - F Soldier