- Features

- Qualification

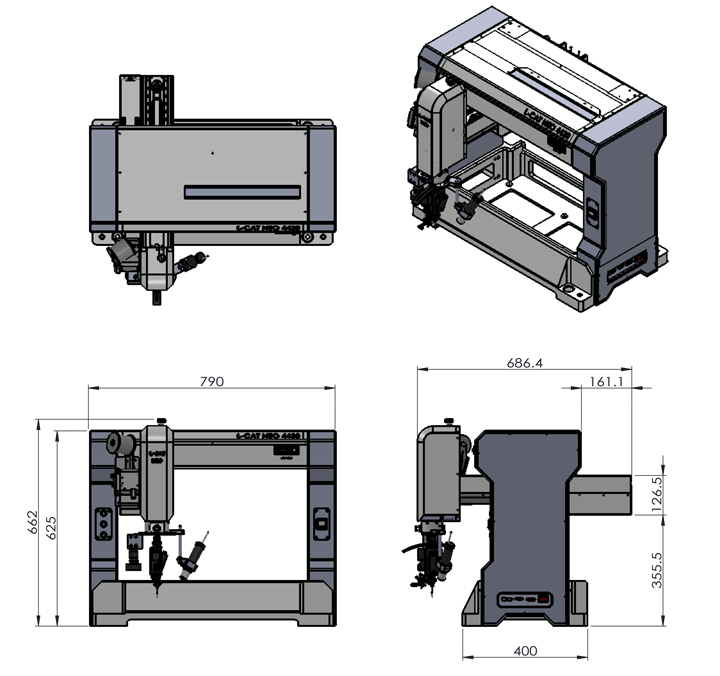

- Outer size

- Application

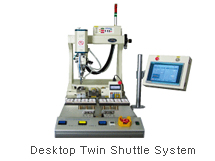

| It is a next-generation soldering robot with various functions required for soldering that responds to production methods such as InLine and Desktop, and data management is a high-function soldering robot that can be executed on mobile devices such as PCs or smartphones. |

|

|

|

|

|

| ||||||||||||||||||

|

| ||||||||||||||||||||||

|

- X,Y High-speed soldering and precision soldering at 1200 mm/sec |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||