- Features

- Qualification

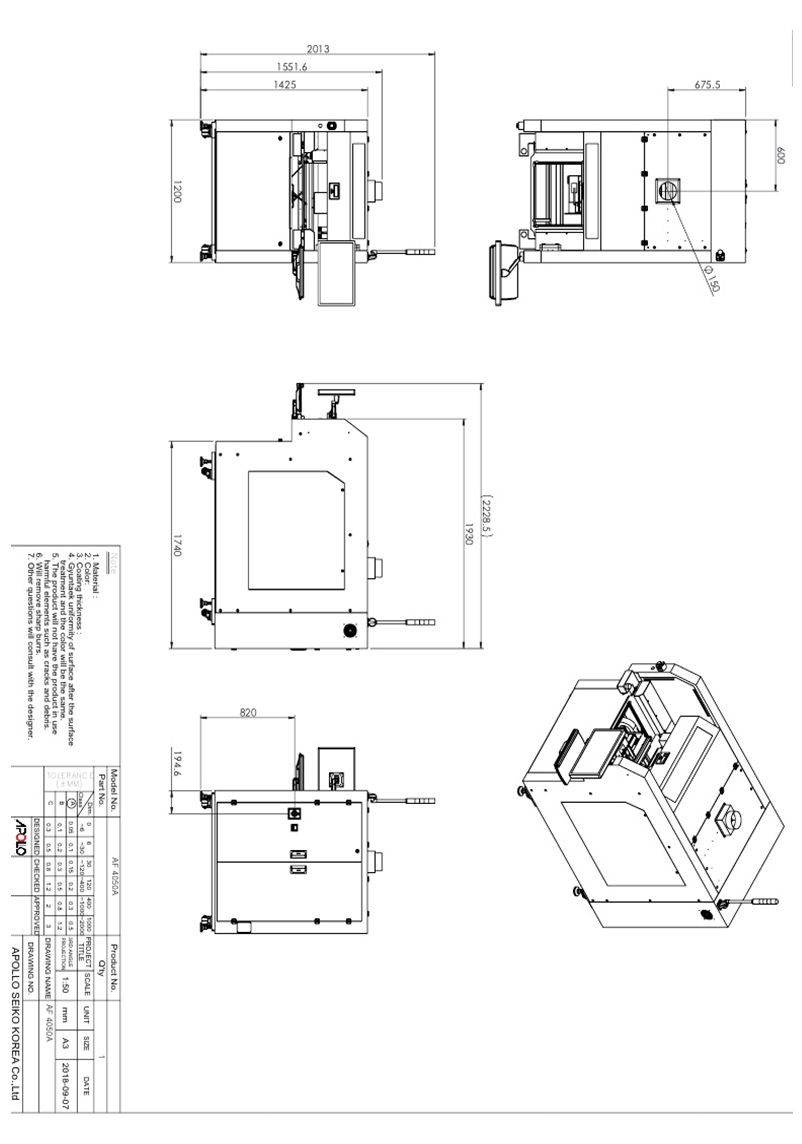

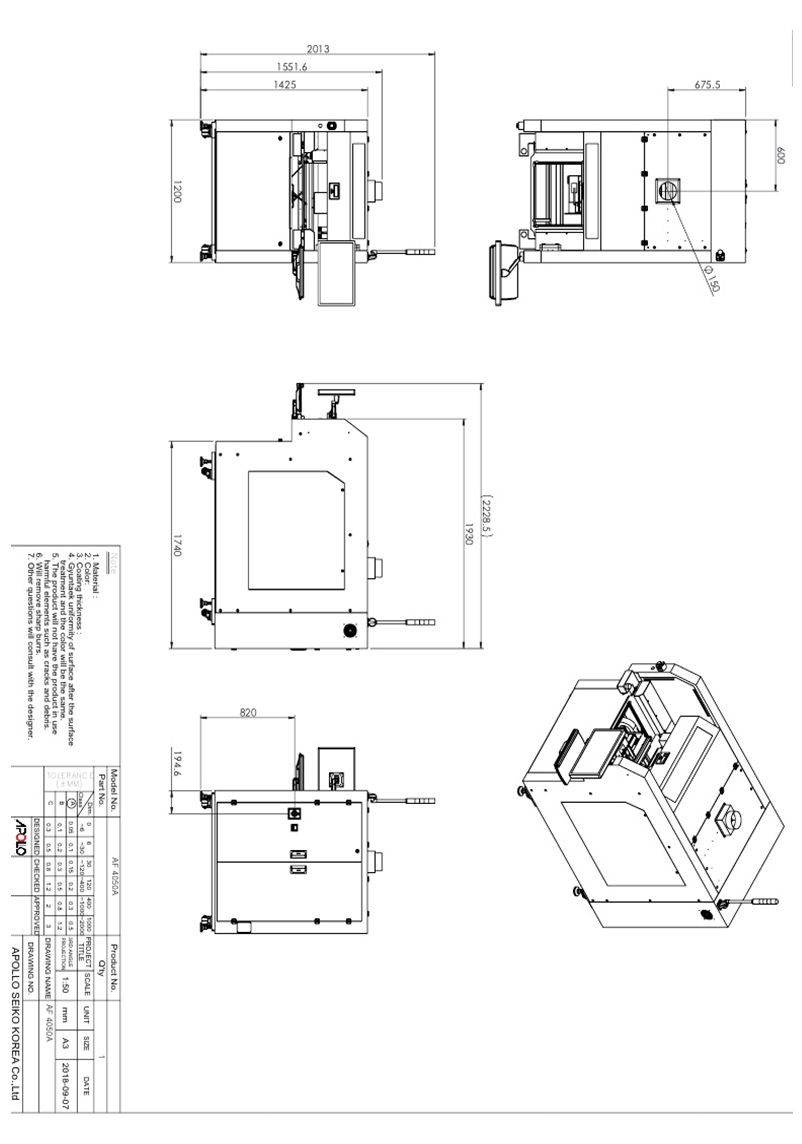

- Outer size

| Affordable selective soldering facility where flux application + preheater + soldering work is possible in 1 module with off-line facility |

|

|||||||||||||||||||||||||||

| Affordable selective soldering facility where flux application + preheater + soldering work is possible in 1 module with off-line facility |

|

|||||||||||||||||||||||||||