- Features

- Qualification

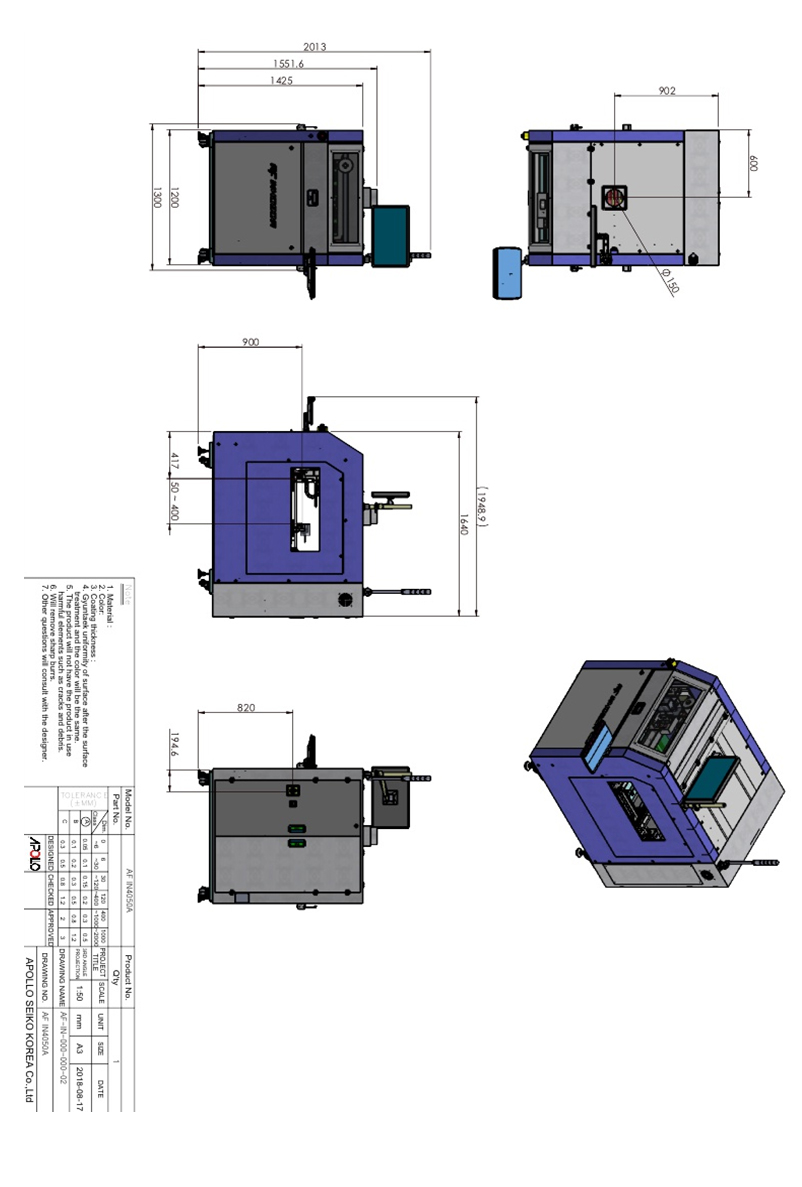

- Outer size

AF IN4050A

Home > Products > AF CF EF seires > AF IN4050A

| In line facilities affordable selective soldering facilities for flux application + preheater + soldering operations in 1 module |

AF IN4050A Integrated In line (flux application-preheater-soldering) facility, configured with optimal specifications for productivity and quality and equipped with various management functions

AFIN4050A Key Features (3Module Inline)

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||

Automatic classification height correction

Automatic classification height correction