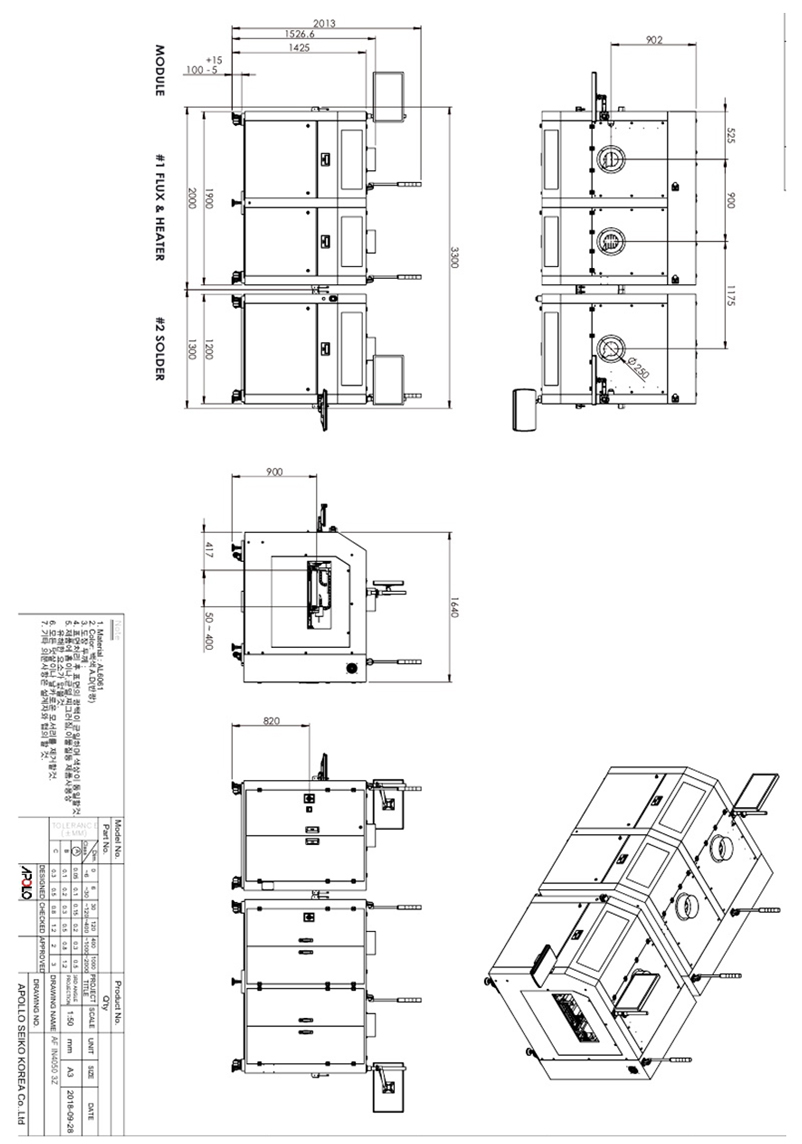

| System Configuration |

1. X, Y AC SERVO

2. CHAIN CONVEYOR UNIT

3. Flux (dot) units

4. Fiducial Mark Vision

5. Real-time monitoring camera

6. Monitoring

7. PCB width automatic setting conveyor |

1. CHAIN CONVEYOR UNIT

2. Top & Bottom 3 Channels

(Double Side Heater)

3. PCB width automatic

setting conveyor

|

1. X, Y, Z, RAC SERVO (R=Sorting Motor)

2. Roller conveyor unit

3. automatic lead supply unit

4. Check lead classification height and auto-calibrate

- Touch Probe Method

5. Fiducial Mark Vision

6. Check the temperature of the nozzle end and Correction Unit

7. a real-time monitoring camera

8. PC (body, monitor, keyboard, mouse)

9. TOP 3 Channel Temperature Maintenance Heater

10. PCB width automatic setting conveyor

|

| SPEC |

1. Micro Dropjet Flux Unit

2. Flux tank pressure

- 30 kPa

3. Flux Tank Capacity

- 2 liters (liter)

4. Fluxing method: Dot

5. X, Y axis AC SERBO speed

- 0~500mm/sec(±0.05mm/sec)

6. X, Y-axis straight line and arc interpolation

7. Chain conveyor speed

-Flow speed: Minimum 600 rpm, maximum 1700 rpm

-Width speed: Up to 20 mm/sec

8. Conveyor Load Weight: 5 kg

9. PCB reference mark automatic position correction

- ±0.1mm, application of vision

10. Direction: L→R (default) R→L (optional)

11. an exhaust system

- Size: Ø 150

- Air flow rate: Max. 356 m3/hr

[Optional]

1. Flux detection sensor

|

1. Preheater type

- Top 3ch & Bottom 3ch

- IR heater, RS485

2. Temperature control range of IR heater

- 50~150℃ (Top & Bottom)

3. IR heater consumption

- Upper: 1 kW X 6 ea

- Lower : 1 kW X 6 ea

4. Chain conveyor speed

-Flow speed: Min. 600 rpm, Max. 1700 rpm

-Width speed: Max. 20 mm/sec

5. Conveyor Load Weight: 5 kg

6. Direction: L→R (default) R→L (optional)

7. an exhaust system

- Size: Ø 150

- Air flow rate: Max. 356 m3/hr

|

1. Lead Tide Consumption Power

- 2.0 kW (±1℃ hot N2 support)

2. Temperature control range of lead tank

- Max. 400℃

3. lead capacity

- 6.5 kg

4. Nozzle base type

- Screw type (Optional: Magnetic type)

5. Temperature control range for N2 heater

- 150~260℃

5. X, Y axis AC SERVO speed

- 0~500mm/sec (±0.05mm/sec)

6. X, Y-axis straight line and arc interpolation

7. Roller conveyor speed

-Flow speed: Min. 600 rpm, Max. 1700 rpm

-Width speed: Max. 20 mm/sec

8. Conveyor Load Weight: 5 kg

9. PCB Fiducial mark auto-position calibration

- ±0.1mm, Vision applied

10. Check lead classification height and auto-calibrate

- ±0.1mm

11. Classification RPM Precision

- ±5rpm

12. Detection of nozzle end sorting temperature: ±2℃

(Thermocouple방식)

13. automatic lead supply unit

- 5kg, Ø2 or Ø3

14. Lead level sensor type

- Proximity sensor

15. Automatic maintenance of solder levels in lead tanks

16 Automatic nozzle cleaning

- Sponge friction type, capacity 30cc

- Water-soluble flux DF 500

17. Direction: L→R (default) R→L (optional)

18. an exhaust system

- Size: Ø 150

- Air flow rate: Max. 356 m3/hr

19. Program Teaching

- Live Teaching

- Scan image teaching

- Gerber Data teaching

- Extemal Gerber,

Scan image teaching

20. Program Capacity

- Flux job, Solder job, Garber data

: More than 1,000 files

21. Multilingual Support

: The U.S., Korea, Japan, and China

[Optional]

1. Loaders and Unloaders

2. N2 purity meter

3. Storage of soldering images and soldering conditions

History Management (MES)

|

Automatic classification height correction

Automatic classification height correction